Everything That You Must Learn About Carbon Fiber For Industrial Manufacturing

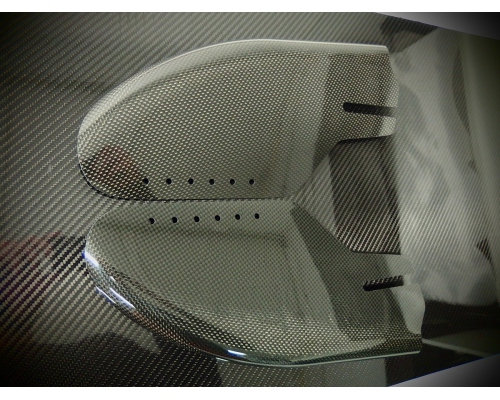

It is not an exaggeration to claim that carbon fiber has emerged as one of the most demanded

materials for various manufacturing purposes. Carbon fiber can replace different metals since it

offers top-notch sturdiness. You can find many carbon fiber manufacturing companies which

experience a massive surge in demand nowadays.

So, what is carbon fiber, and how can you benefit from it? Carbon fiber, also known as graphite fiber,

is a strong and sturdy material for manufacturing various items. The benefit is the lightweight

feature of this material. Despite offering top-class sturdiness, carbon fiber remains lightweight.

Unique Things to Know about Carbon Fiber

The term carbon fiber is known to everyone, though people do not know its details. In the following

section, you can find some exclusive facts on carbon fiber.

1. Carbon Fiber Is from Europe

Carbon is everywhere, though the largest manufacturer of carbon fiber is in Europe. The raw fiber

that is available in nature is known as Polyacrylanitrile fiber. Carbon develops into fiber due to

enormous underground heating. Many European countries have coal mines, and carbon fiber has

been derived from such mines.

2. Different Types of Carbon Fibers

Carbon fiber is not a homogeneous material quality, as the quality varies from one material to

another. Therefore, there is a grading system to grade the quality of the carbon fiber. Standard-

grade carbon fibers are easily available, while ultra-high-modulus carbon fiber is rarely available.

3. Firmer Than Steel

Astonishingly, carbon fiber is tougher than steel, though it is lightweight. The same volume of steel is

heavier than carbon fiber. But carbon fiber will remain unharmed even after a long time. Plastic is

known for its durability, and carbon fiber has better durability than plastic.

4. Carbon Fiber Damage Repair

Repairing a plastic item is difficult once it gets damaged. But carbon fiber is different, as the damage

is repairable. Therefore, carbon fiber increases the longevity of the product. Purchasing an item

made of carbon fiber will serve for a long time.

5. Beware of the Fake Carbon Fiber

Products manufactured by carbon fiber manufacturing companies are long-lasting and carefree. You

cannot damage such products easily and enjoy portability due to the lightweight material. Such

benefits of carbon fiber have introduced many fake carbon fiber sellers. You should avoid the face

items and purchase the authentic ones for a durable solution.

The History of Carbon Fiber

A discussion on carbon fiber composites will remain incomplete without knowing the history of the

material. In 1879, Thomas Edison experimented with baking cotton threads at a high temperature.

Due to the high heat, the cotton threads get carbonized into an all-carbon fiber filament. This is the

first instance that tells about the presence of carbon fiber.

Carbon fiber eventually became a more notable thing for industrial manufacturers when high-

performance carbon fiber was manufactured. However, such carbon fiber has become inefficient

nowadays. Since it contains only 20% carbon, it does not offer the strength and flexibility of the

industrial standard carbon fiber.

In 1963, manufacturers started realizing the strength and usefulness of carbon fiber. However,

carbon fiber was available in low quantity at that time. As a result, a few British industries used

carbon fibers for manufacturing a few goods. Carbon fiber has become a consistently growing

popular material since that time.

The Industrial Manufacturing Process of Carbon Fiber

The prepare composites from the mines are unsuitable for industrial manufacturing. Therefore, the

material undergoes various industrial processes to become suitable for manufacturing multiple

things. At first, the long strands of fibers have been collected. In the next step, these strands of

fibers underpass a highly heated environment.

While passing the fibers through the high-heated environment, it is ensured that the material does

not come in contact with oxygen. As a result, carbonization takes place. The atom inside the fiber

frequently vibrates due to carbonization.

Such a process develops a unique fiber that consists of tightly interlocked and long carbon atom

chains. Eventually, it results in the segregation of non-carbon and carbon atoms. In this way, the

carbon fiber has been processed and made suitable for multiple industrial uses. The ultimate quality

of the carbon fiber also varies depending on the processing techniques.

The Uses of Carbon Fibers

Nowadays, you can see the uses of carbon fiber for multiple purposes. In the following section, you

can section, you can find a guide to the use of carbon fiber in different industries.

1. Automobile Manufacturing

Carbon fiber can bring revolutionary changes to the automobile manufacturing industry. Developing

a lightweight automobile is the aim of all manufacturers, as lightweight vehicles offer better stability

and speed. Using different metals for automobile manufacturing leads to the enhanced weight of

the car. As a result, the desired performance from the vehicle does not come.

Carbon fiber can be a solution in such cases, as the material is extremely lightweight. On the other

hand, it will not compromise the sturdiness since carbon fiber is strong and flexible. According to the

researchers, carbon fiber is stronger than steel.

2. Sports Gear Manufacturing

Sports gear manufacturing is another field where you will use carbon fiber extensively. For example,

tennis rackets are manufactured with carbon fibers nowadays. There are two benefits of using

carbon fiber to develop sporting equipment. Firstly, the accessories and products will become

lightweight. Secondly, carbon fiber makes sporting equipment long-lasting.

3. Aircraft Manufacturing

Carbon fiber has extensive use in aircraft manufacturing, as the material is lightweight and sturdy. In

aircraft manufacturing, the manufacturers seek materials that are strong. At the same time, strong

materials should be lightweight. Carbon fiber is a rare material that precisely serves both of these

things.

4. Motorbikes and Cycles

Carbon fiber can withstand high heat and pressure. Therefore, it can become an ideal material for

automotive parts manufacturing. Moreover, the material is suitable for manufacturing cycles and

motorbikes.

An efficient carbon fiber parts manufacturing facility should procure high-quality carbon fiber. On

the other hand, buyers should find sellers that offer goods that are made of authentic carbon fiber.